We offer high-end precision manufacturing of outstanding quality.

For us, no structure is too complex and no challenge too big. From the idea to the finished product, we design, develop and manufacture high-precision parts. Whether high-alloy steels, plastic, aluminum, titanium, ceramics or other materials, whether anodized, chemically nickel-plated or chrome-plated, for a flexible and effective implementation of your ideas, we are the partner at your side. Benefit from our experienced employees, 50 years of experience in production and a modern and innovative machine park.

Referenzprodukte

Shielding satellite

Application: Shielding of satellite from cosmic radiation

Size: 310mm x ᴓ 200mm

Material: High-tensile aluminium

Challenges: Highest requirements regarding precision and surface finish

Shovel Mars mission

Application: Collecting of samples

Size 50 x 50 x 20 mm

Material: Niobium steel

Challenges: Surface roughness Rz 1, Fitting ±2µm, Shape and positional tolerance 0,01 mm

Housing Pathfinder

Application: film industry

Size: 122 x 85 x 39 mm

Material: High-tensile aluminium

Batch size: >100

Challenges: Angular Accuracy ±5‘‘, Surface roughness Rz 1

Axial piston pump

Application: F1 engine

Size: 20mm ᴓ 28mm

Material: High-alloy steel

Challenges: Fitting ±1µm, Surface roughness Rz 1

Distributor

Application: DTM

Size: 40 x 40 x 30 mm

Material: Titan

Challenges: Fittings <10µm, Connecting threads, Micro drilles holes, Shape and positional tolerance 0,01 mm

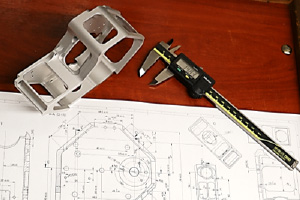

Simultaneous 5-axis milling is the most advanced form of machining.

The capabilities inherent in simultaneous multi-axis milling allow for the greatest variety in part forms. Machines capable of 5-axis milling can achieve complex geometries in one setup alone.

In addition, shorter, more stable cutting tools can be used, allowing for higher cutting speeds and less cutter vibration. This once again allows for the maintaining of tolerances in micron ranges.

We exclusively use the highest-precision machine models available from the renowned German manufacturer DMG. Due to our excellent partnership with DMG, immediate service, with 98% guarantee of spare part availability, is guaranteed in case of difficulty and we can thus always assure delivery on time.

We use modern turning centers from the leading Japanese precision manufacturer Okuma. They have full 4-axis synchronized machining capability, dual tool revolvers and extra-massive guides with the highest-torque drives available. This allows us to meet the highest accuracy requirements irrespective of the difficulties normally inherent in especially tough or hard materials.

Our turning operation allows for micron-range tolerances and thus eliminates the need for customarily time-consuming finishing steps. We offer optimal efficiency at this level of accuracy and maintain low cycle times and unit costs. Our turning operation can work with diameters up to 410mm and machining lengths of up to 1000mm.

DENZ has always stood for a unique feel and look in the industry. In addition to blasting and tumbling, DENZ has diverse cooperation partners for polishing, anodising, painting and powder coating. For functional surface treatments, DENZ has extensive experience regarding heat-treating, hardening and nitriding. The processes used in achieving the legendary surface quality of DENZ film products can thus be applied to your parts.

We work exclusively with selected, experienced partners who clearly understand our requirements and how to realise them.

In part manufacture, we are able to offer surface roughnesses of Rz <1µm (≙ Ra 0,03 – 0,25 µm)

Our know-how is your head start. With our 50 years' experience, our comprehensive technical knowledge and our passion for perfectly-matched solutions, we are eager to support you in all phases from your idea through to its realisation.

Together, we can formulate your requirements and all resulting demands on your ordered work. Our expert staff will analyse all relevant aspects and efficiently plan the necessary process and work steps. In this way, we can identify risks before they become dangers, and thus offer you an effective, trouble-free and reliable manufacturing process.

Take advantage of our many years' experience and contact us today!

At DENZ, we always wish to make all your required processes run as efficiently as possible. In order to reduce time-consuming searching for suppliers of purchased parts, often then resulting in further delays due to delivery times, we also offer assembly in addition to the manufacture of parts.

We can take on the work of purchasing all additional components, arranging all surface treatments and finally assembling the manufactured parts in accordance with your bills of materials and drawings. In this way, you benefit from our high quality standards throughout the entire production process and avoid unnecessary complexity, risk and possible resulting costs.

We would be pleased to discuss custom solutions for individual builds or series-production assembly with you.

Referenzkunden